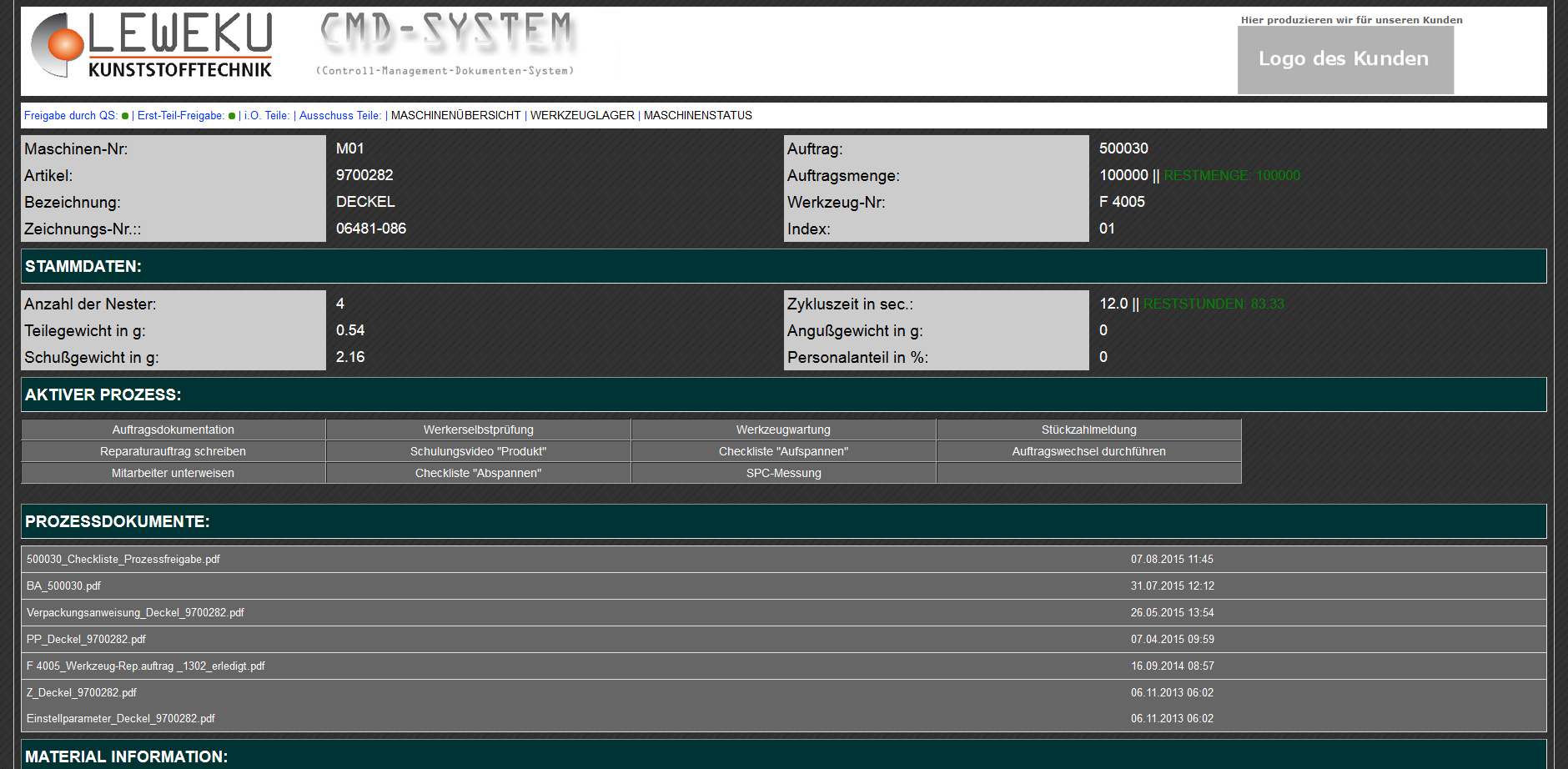

- Each machine is equipped with a touch screen. All important information about customers, product and the required quality can be retrieved in REAL TIME by every employee.

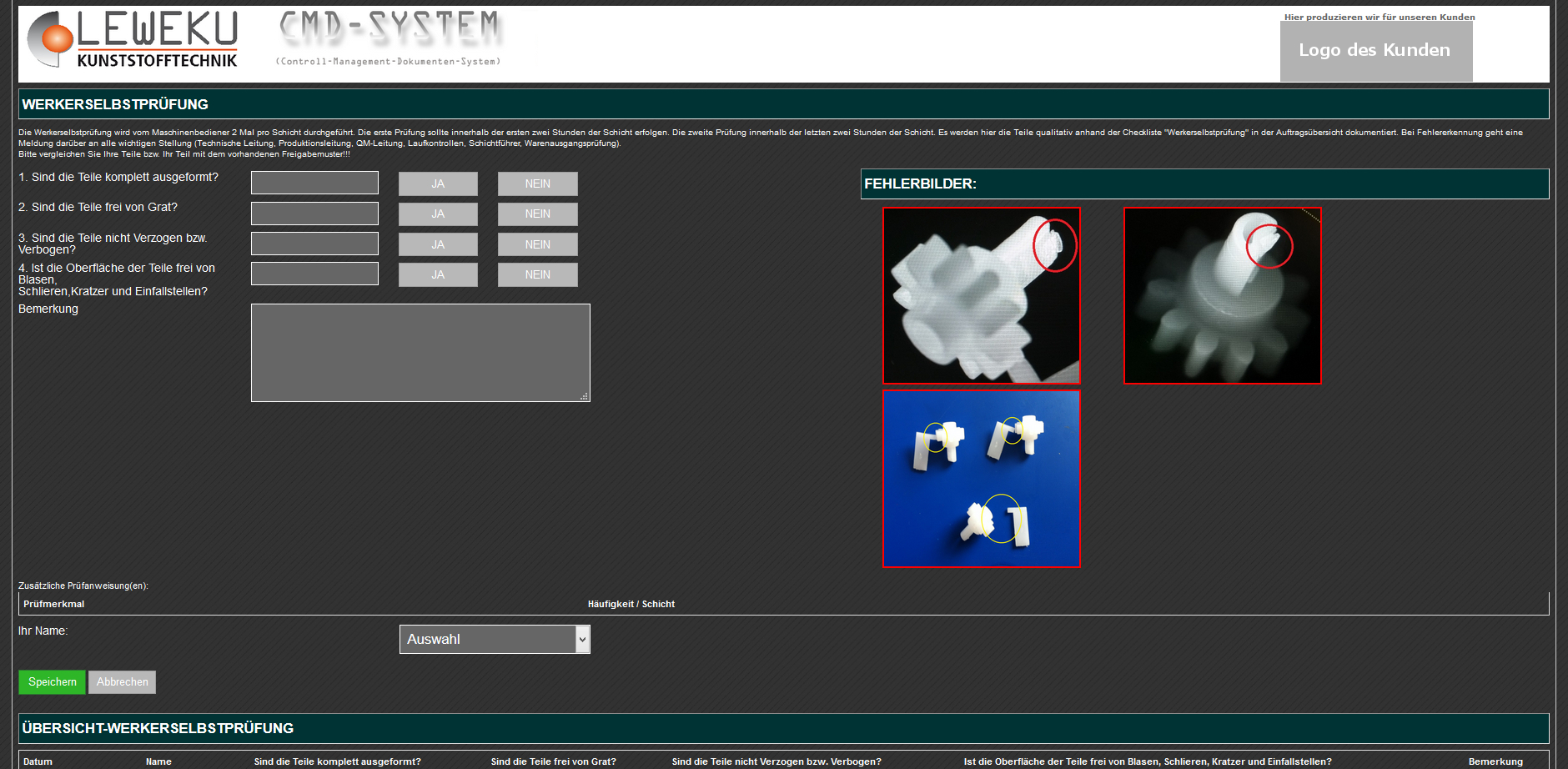

- Error images are displayed immediately

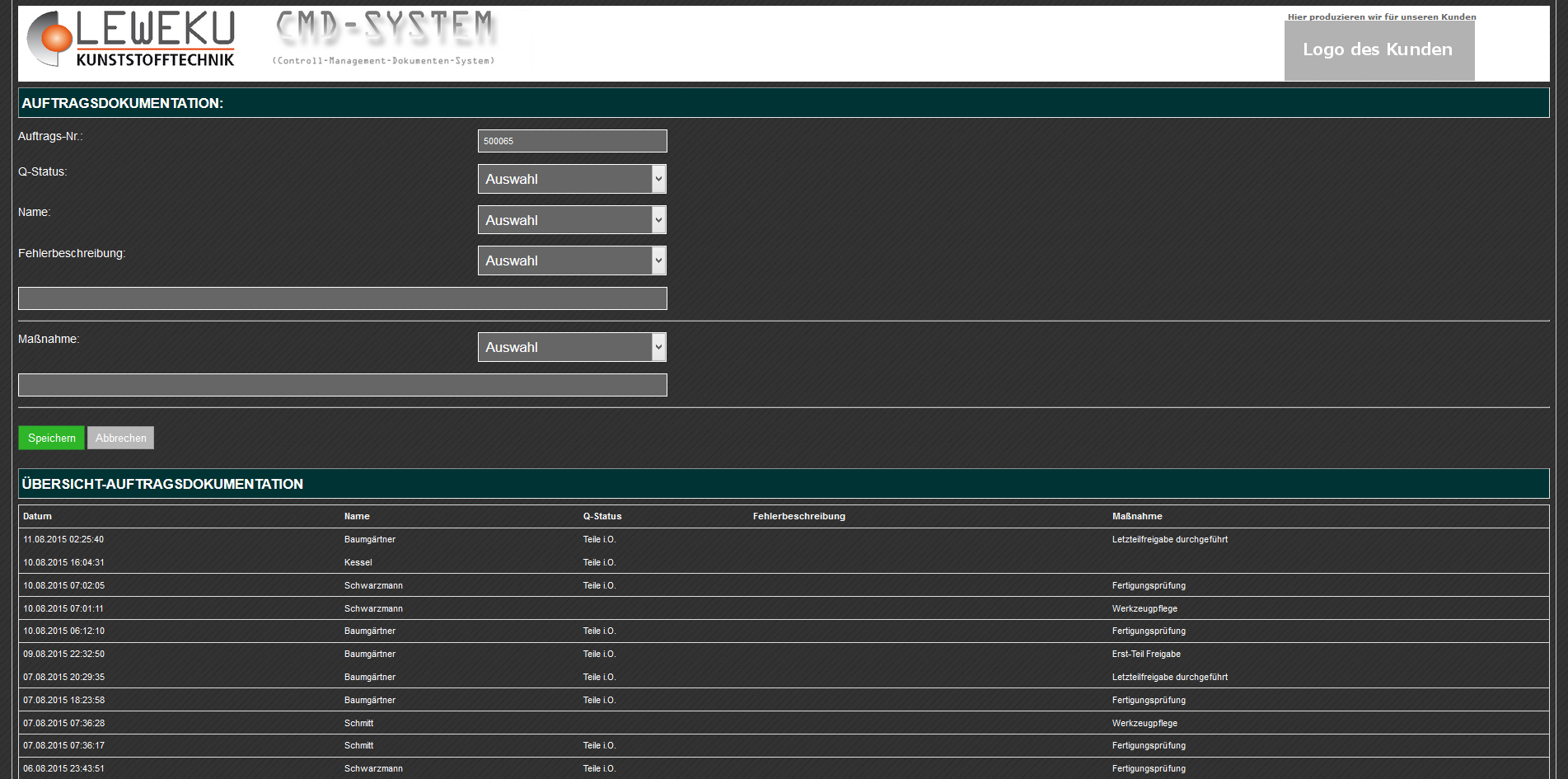

- Every process change is continuously documented. All changes to the process are traceable!

- Our production process is continuously checked and documented by our employees.

- Our production process is checked and documented again at the start of production using a checklist.

- Employee training takes place directly at the machine.

- Drying parameters stored directly on the screen.

- Product videos, training videos and information are called up directly at the machines or assembly workstations.

- a proprietary development of LeWeKu Kunststofftechnik GmbH